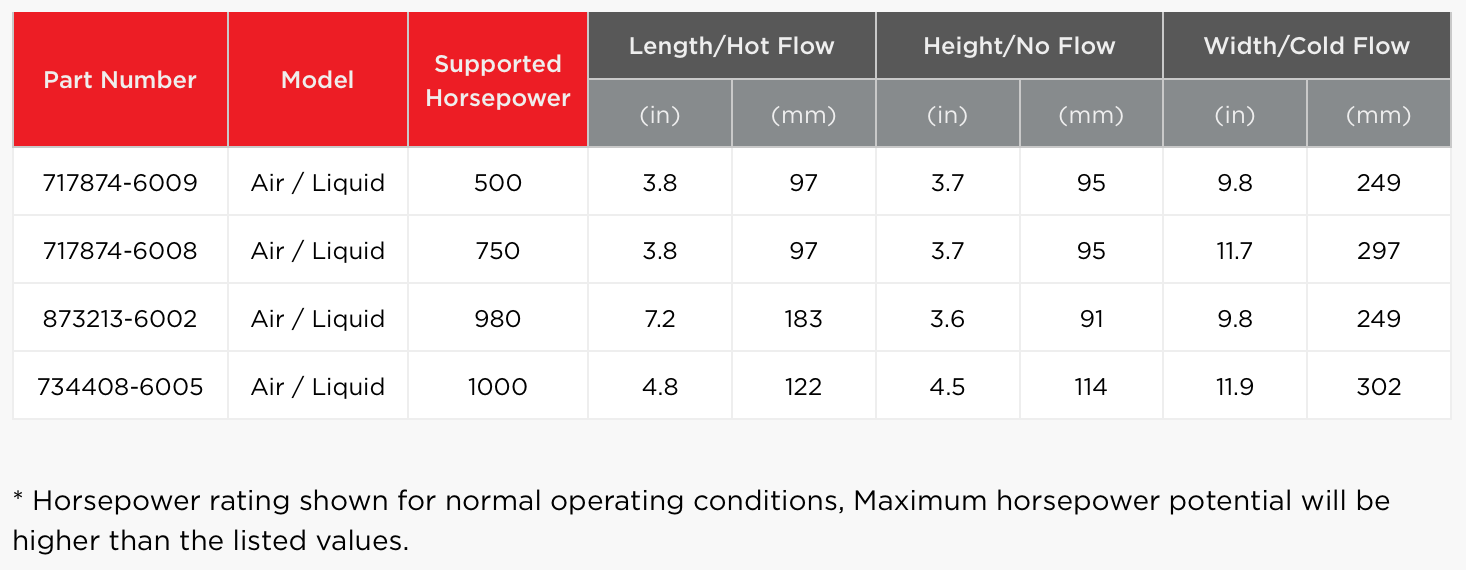

Description

Garrett Advancing Motion - Air-to-Liquid Intercooler Cores

Garrett intercoolers offer superior fatigue protection for the high boost pressures and temperatures of today’s extreme engines.

Performance Intercoolers

Garrett performance intercoolers and intercooler cores work together with the turbocharger as part of the total induction system. When air is compressed in the turbocharger it gains a lot of heat. Hot air is less dense and therefore is not able to produce as much energy because less can be fed into the engines cylinders. The job of the intercooler is to remove heat from the charge air making it more dense. The denser charge equals more air and fuel reaching the engine and that translates to more horsepower.

Intercooler Construction

Garrett intercooler cores are bar and plate horizontal flow design. Charge air from the turbo flows within enclosed passages in one direction, with separate cooling passages flowing cooler ambient air in a perpendicular cross-flow pattern to the charge air. In bar and plate designs the passages consist of plates on top and bottom with fins in between. The passages are enclosed by bars on either side depending on if it is a charge air passage or an ambient air/cooling passage. Passages are stacked alternately until the desired stack height is reached. On the sides of the stacked cores, added to the final passage is a side plate of thicker material to provide structural integrity, protect the more delicate fins, and provide a surface for welding on end tanks if desired.

Heat Transfer

How does the intercooler remove heat from the charge air? There are three types of heat transfer modes, but the bar and plate intercooler relies on Conduction and Convection to extract heat from the charge air. Conduction is the transfer of heat to materials that have direct contact with each other. Convection is the transfer of heat from one place to another by movement of air. As you can see in the image below, the bars, plates, and fins alternate direction and flow and all play a part in extracting heat from the charge air. The charge air fins transfer heat from the charge air to the plates and the ambient air fins transfer the the heat from the plates and the ambient air cools the fins. The process repeats as long the car is moving or until the core gets heat soaked.

Fin Density

Fin density is measured in FPI or fins per inch. Each fin surface counts as one fin meaning there are two fins per wave. Fin stacks start off as flat sheets of aluminum that are fed through a special machine where they are bent to the desired FPI per row height and length. Garrett manufacturers around 20 different air-to-air and air-to-liquid intercooler cores supporting a range of horsepower from 310 up to 1260. Each of those cores are different in length, width, and height to meet the needs of different performance enthusiasts.

Garrett Intercooler cores utilize a combination of fin density depending on the flow path of the core. For example, the cold flow path or the front of the intercooler commonly has a higher density fin count to allow for better thermal performance and cooling. Core width/ cold flow can range from 3 – 5 inches so higher fin density is critical with the short span the ambient air travels across to cool the charge air passages. Additionally, the cold air passages are not sealed or pressurized like the charge air passages, so your ambient air flows through, cools the hot passages and evacuates into the engine compartment.

Hot flow passages have a longer run spanning from 11-28 inches in some intercooler cores. The hot flow path is a series of sealed chambers with fins spanning the entire length. There is a lot of surface area for heat transfer to take place and for that reason, the hot chambers have a lower fin density. This also helps reduce pressure drop as the charge air travels from one side to the other.

Pressure Drop

Pressure drop is the difference in pressure between two points caused by flow resistance. An example of pressure drop is when the air pressure leaving the intercooler is less than the pressure that went in. You may never actually see this happening because your turbo will work harder (spin faster) to deliver the correct PSI to the engine. The faster a turbo spins the hotter the air is so it’s critical to use an intercooler that has a good balance of fin density so you don’t overwork the turbo.

Think about driving down the road with your hand out of the window and your palm facing forward. Your hand is interrupting the flow of the air and it must find a way around your hand to pass. Now imagine you and 10 friends in a limousine with your hands out of the window one after another. The last person in line will not feel the same flow as the first person because of pressure drop.

Estimate shipping

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.